Building a 4 Element Cubical Quad

There are many reasons you should considering building your own antenna. First you can taylor it to the needs of your communication (local or DX and optimize it for the frequency you talk on) and to the needs of your environment (make it strong if you live in a harsh one where ice and wind is a problem). There is the extra part of knowing you did it yourself. To the best of my knowledge, only one company is producing a commercially available quad (Signal Engineering, Hy-Gain did) in the U.S. Another reason that you might build is you might be able to build a beam more cheaply than buying a commercial one (do not be surprised how much more you might have to spend to complete the project than you anticipated however). I assure you, there is nothing like stomping locals on DX contacts. Until your friends catch on and start building their own too (and co-phase them).

Basically, I am going to mainly discuss the setup I used on my 4 element cubical quad. You can build a cubical quad with any number of elements, but make sure you read my section under “Feeding the Antenna” section if you are going to deviate from 4 elements. I seriously recommend building a 4 element quad. Four elements gives the highest gain to size ratio of any type of beam in existence. If you go more than 4 elements the gains are negligible, less than 4 elements and you could have a bit less than you get with 4 elements. These are the simple reasons I recommend the four element quad.

Let’s first discuss some design principles that all beam’s (Quads and Yagi’s) have. Antenna gain, front-to-back, front-to-side and bandwidth are the 4 properties of an antenna that must be balanced to suite the designer’s needs. It is possible to maximize all these properties but then we would be coming up with a design that is a happy medium. You could take the road of designing for the highest gain (or any other principle), but this will cost you somewhere else (lower F/B, bandwidth, etc.)

Lets look at the factors that influence these properties. There are two items that effect the four characteristics of the beam, elements length and element spacing.

Element Lengths

This and the next section are going to refer to Figure 1. Figure 1 has labels for each of the beams dimensions we are going to talk about now. Element lengths play a role in the overall performance of the antenna.

Figure 1 – The important dimensions we must calculate for the frequency you choose. The R1,DR1,D1 and D2 dimensions are just for 1 side of their respective element.

To calculate dimension you can refer to this Quad Antenna Calculator

Element Spacing

The element spacings that are calculated are just suggested spacings. Those numbers do not have to be followed to the exact inch like the element lengths should be. Usings spacings wider than the ones suggested yield higher gain at the cost of front-to-back ratio. So then, if you use closer spacings, you get better front-to-back at the cost of gain. The spacings I have given are a good mix of the two in my opinion. Closer spacing for CB frequencies is from about 4′ to 5′. Wide spacing is from about 5′ to 6′. This is for 4 elements. Once you start adding more than 4 elements, you can go to an even wider spacing (than 6′) for the directors. If you end up making your 4 element quad framework like I suggest below you will have to stick to a S1 – 65″, S2 – 56″ and S3 – 65″ spacing.

Beam framework

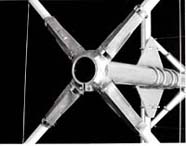

We are now ready to get started on the supporting structure for the wire elements. You should have already read the section on “Cubical Quads” under then antennas types to give you an idea of what we are doing here. Figure 2 shows a sample of a parasitic element. We need to insulate the wires from the boom. You cannot just simply just make the spreader arms (the X shaped supporting structure) out of aluminum and then just insulate the wire at the tips of the spreader arm. If you do that you will have too much metal supporting the wires and this will badly interfere with the tight radiation pattern that you are trying to achieve. The supporting structure will actually start becoming part of the antennas, grossly de-tuning it. Ideally, you would make the boom and arms totally from an insulating material (such as fiberglass). If you are skilled enough (and have the money), do it that way. For most of us, we need to at least use an aluminum boom for the antenna (for strength reasons). Your next best bet is to use fiberglass spreader arms attached to an aluminum boom. You can get all the materials you need (if you cannot get them locally) from a company called MAX GAIN SYSTEMS, INC. They sell booms, fiberglass spreader arms, spreader mounts..and everything you need to build a quad plus some more info on design considerations. Unfortunately this route is expensive also. I have not checked into comparing these two options, but it might be cheaper to buy a commercial Quad, if you need to buy all the parts rather than buying all the pieces from Max Gain Systems. If anyone determines the pricing differences, let me know! You need at least a 11 foot boom (to satisfy the minimum suggested element spacing) and enough material for all your elements. The spreader arms (4 for each element) are about 6 1/2 feet per spreader. This means you need to get enough fiberglass and aluminum to make enough elements. The spreaders must be adjustable, meaning they should be able to be lengthen or shortened by a couple inches to tension the element wire, do not think the lengths that were caculated above are the exact sizes you need. A boom to mast mounting plate and some kind of spreader mounting device (sometimes called a spyder or hub, one is pictured below) are required. I recommend that you not use more than 36″ inches of aluminum per spreader arm or you will get start to get pattern deformation. The less aluminum you have to use on the spreader arm the better, where an arm totally made up of fiberglass is ideal.

The cheapest way I have found to build this antenna is to find an old Moonraker 4. If you can find a Moonraker 4 that has at least the Boom and hubs (that are still ok to use) you are halfway home. Figure 3 shows my 4 element quad built with old Moonraker 4 parts on a 40 foot tower. I said you are limited on element spacing if you use my design (Moonraker 4 parts), because you will have to stick with the Moonraker 4 element spacing (S1 – 65″, S2 – 56″, S3 – 65″). I have found these spacing’s to work great for 11 meters. My beam has a good mix of gain and F/B (Mine is designed for 27.555MHz). After you get the Moonraker parts, you will still be short on fiberglass rods (you will need 12 more of them). I was lucky enough to find fiberglass electric fence posts that worked perfect, for free. You could try using bamboo, or wood, but you must weather proof them well, or you this antennas will not last. Ideally, fiberglass is best. Do not even think about ordering new Moonraker fiberglass rods, they are 10$ a piece (that would be 120$). Max Gain Systems also sells pieces to attach the element wire onto the end of the spreader arms. In my case, my fiberglass rods were big enough for me to drill through and pass the wire. This would split the Moonraker fiberglass arms, so you can use the stock way to attach the wire, but if you order other fiberglass rods, you might need to get creative on how to attach the wire to the spreader ends. You can always buy the commercial parts however. Most people say not to drill through the spreader arm, because water will get inbetween the wire and spreader arm, freeze, expand and crack the end of the spreader arm. I haven’t had trouble, but when I take it down to redo it, I am going to seal the holes with some kind of compound. My beam has been in operation for six years without any type of mechanical problems.

(12/1/98)

I have just discovered that the fiberglass I used is available for sale on line, and it is cheap! It is a total bargain, and is the way to go if you need to make spreader arms. HERE is the link to just on

e dealer I found. You can find others by searching for keywords like, “electric fence posts fiberglass”. If you find better prices, let me know ! The proper name of the fiberglass fence posts is “T-Posts”, because they are shaped like a “T”. If you have farm supply stores around, more than likely you can get them there. I will be adding close up photos of my spreader assembly, I used pipe clamps to attach the fiberglass to the outside of the aluminum arm.

“Fiberglass T Post”

Also, I just dropped my tower down for the first time in 6 years..and the effects of the environment are suprising! First off, I read this at some fiberglass distributors site, but I never thought about it. My fiberglass arms are looking worn. The fiberglass is fraying from the rod and they are really stained. They are still strong, I was bending them good. But I really think its necessary to paint the fiberglass with a good quality enamel (Rustolem or Krylon). I read to paint the spreaders flat black, but that does not make sense to me. I am going to paint mine flat white. White reflects heat better than black. The paint offers UV (Sunlight) protection…which destroys mostly everything it hits over time.

Another word to the wise about fiberglass…always use gloves to handle fiberglass, if you don’t your hands will be itchy and burn from the fiberglass strands that will stick in your skin.

Figure 2 – Quad parasitic element. Aluminum and fiberglass arms are held together with pipe clamps. This whole assembly shown slides onto the boom (the hub’s center fits onto the boom).

The Element Wires

The next step after designing and getting our support structure together is to get the elements wires measured and ready to place on the spreader arms. First the choice of wire. There are several choices of wire you can use, solid, braided, etc. There are two that I could suggest. At least #12 wire should be used regarding bandwidth. #10 would be even better, but your spreaders arms must be strong because when #10 loads up with ice or wind, its going to stress yours spreader arms to the max. My choice is #12 solid wire (not braided). Also keep in mind the wire should be bare, not insulated You could also choose a special wire for antennas that people use called “copperweld”. It is a steel wire that has a copper coating on it. It is suppose to be stretch resistant. After awhile, soft drawn copper wire will stretch. That’s what they say, but I prepared my #12 soft drawn wire by stretching it. Figure 4 shows a rather weak way to stretch the wire. Instead of hooking it to a nail, I wrapped it tight around a tree, and stretched the daylights out of it. You can actually feel the wire stretching as you pull on it. Another thing I did (to really straighten the wire) was to start where I hooked the wire to the tree, loop the wire around a large screw driver and then pull the screw driver down towards the other end of the wire One hand on one end of the screw driver, the wire in the middle looped around it, and my other hand on the other end of the screwdriver (click HERE for a visual example of this method). I also usually place a rag around the screwdriver so that the metal screwdriver does not score the soft copper wire. This will take out all the kinks that are in the wire and make it really straight (that’s good). Its best to figure on getting about 40 feet for each element and an extra 40 feet in case you accidentally screw up (badly kink a wire, snap it from pulling too hard, etc.)

Figure 4 – The way to stretch and measure your wire. Mark the corners of the wire with a precise mark. You could use something like red paint, but keep the mark exact..in other words do not just spray it on, you should brush it on making it no wider than 1/8″. Do whatever its takes to mark the wire perfectly. I will refer to these marks as “corner marks” because these will be the corners of the element when it is strung.

Next you want to coat the wire with clear enamel. Copper wire will oxidize (“rust”) rather quickly, so you must coat it with a few really good layers of enamel. You could alternatively buy wire that already has enamel on it. You know you got a good coating of enamel on it if you can take your Ohm meter and not get a circuit (infinite resistance) when you touch the wire with the probes. Coating the wire with enamel serves the purpose of keep the beam as efficient as it can be. Since we said RF travels on the outside “skin” of the wire (at CB frequencies), it is a good idea to keep it shiny. You will have less Ohmic loss, and plain better antenna efficiencies if you do this step (do it!). If you are wondering. why can’t I keep the insulating jacket on the wire, instead of getting bare wire…won’t that protect it better? Yes it will but the wire will be heavy and you really do not want that, it will sag too much. Also, if you do use wire with insulation (don’t!) the element lengths calculated above will not be valid, you will need to re-adjust the formulas I used to take into account the insulation on the wire.

Ok, after you picked out your wire and gotten it ready to use, Its time to measure it all out. Figure 4 shows the way to measure the wire the best. You obviously do not need a 50 foot tape measure to measure the wire like shown. It is most convenient to use at least a 10 foot tape measure. Lets suppose we calculated our antenna above and got a reflector element length of 9′ 4 3/8″ per side. Suppose we are measuring out the reflector element. First, mark your first starting point by where the wire is attached to the nail. Be sure to leave a few feet of extra wire before you make your first mark (we will need to bend the wire back and make a connection). Next for the example, measure down 9′ 4 3/8 ” from the first mark, then mark that spot. Do this three more times like the figure shows. Do the other three elements in a similar manner. You are now done getting the wires ready.

Feeding the Antenna

One of the important parts of getting a really good, high gain radiation pattern from the antenna, is to feed it correctly. Under the Coax Basics section, I discussed that coax cable is unbalanced, which means that no current flows on the shield of the coax. The quad (and yagi) are balanced feed antennas, meaning that they require currents to be balanced at their two connection points. If you would just take the coax and hook it straight up to the antenna, what do you think happens? Well, when we look at radiation patterns (of a beam feed with balanced lines), we see that they are symmetrical. If we were to take our coax and hook it straight up, our pattern will get skewed off to one side (shown in figure 5).

Figure 5 – The radiation pattern of the antenna on the left is a 4 element quad feed directly with coax. The radiation pattern of the antenna on the right shows a quad using a device (balun, gamma match etc.) to match the unbalanced coax feed to the balanced antenna. A clean pattern results.

So, what device is used then to convert the unbalanced feed of the coax to the balanced feed requirement of the antenna? We have talked about one device already. The Gamma Match, not only does it simplify tuning, but it acts as a device to match the balanced antenna to the coax. Another device is known as the balun, which is made from the words BALanced-UNbalanced. A balun takes the input from the coax and balances it. It is possible to build your own balun, but, I am recommending that you buy a commercial one. This is one place where its just best to use a professional designed and built piece for your antenna. Figure 6 shows how you can mount your balun to the spreader arm (shown for horizontal polarization). Figure 7 shows a view of the driven element so you can see where the balun is located. On horizontal polarization, I strongly recommend that you drop the coax straight down from the antenna like I have shown. This keeps the coax out of the immediate field of the antenna and prevents the feedline from disrupting the super pattern of this antenna. There is not a whole lot you can do to avoid this if you feed the antenna for vertical polarization (as shown in figure 8) because you can see the coax has to run down the spreader arm. This is why I recommend using horizontal polarization. If you are building this antenna your main reason must be you want the absolute highest gain, little things like dropping the coax directly away are the little things that add up. When you go to get a commercial balun, make sure you go with a current type balun (as opposed to a voltage type). The quad and yagi require balanced current for a clean pattern. Another specification that you need to get is a 1:1 ratio balun. This does not have anything to do with the SWR ratio (we know 1:1 is perfect). The ratio on the balun indicates what ratio it transforms impedance’s at. Since our antenna (the 4 element quad) has a feedpoint impedance around 50 Ohms and our coax is 50 Ohms, that means we want a 1:1 ratio. If we are building a 2 element quad we would need to use a 2:1 ratio balun because the feedpoint of impedance of the 2 element quad is around 100 Ohms. Thus if we were building a 2 element we would need to match 50 Ohms (coax) to 100 Ohms (antenna), and this is a 2:1 ratio. Keep that in mind if you are building a 2 element quad (Yagi’s are different). So, when you go to buy, get a “1:1 Current Type balun” for your 4 element cubical quad.

Here are the two Baluns I recommend, the first is more expensive, but it might be worth it (I have read a lot of good things about it, but I use the second one listed):

| Manufacture: Amidon |

| Model: W2FMI 1:1 HBH50 |

| Info: 5KW, 10KWpeak (Max wattage) |

| Price: $49.95 |

| Link: http://www.bytemark.com/amidon/prbalun.html |

This one is square, and looks like it might be harder to mount on the spreader arm. I am going to try this on my next quad. This one is square, and looks like it might be harder to mount on the spreader arm. I am going to try this on my next quad. |

| Manufacture: Unadilla |

| Model: W2DU (Current Type 1:1 only) |

| Info: HF 1.8 – 30MHz |

| Price: $26.00 |

| Link: http://www.unadilla.com/unadilla/bigsig.htm |

Now we are ready to string the wire on the elements. All we have to do is thread our wire through the spreader tips (through our wire holder). This is where you want to place the marks you made on the wire at the corners (where you wire holder is). This is why you wanted the marks to be exact. For the parasitic elements, take your solder iron and join the two wire ends together. Your marks on the wire should meet at this point. Refer back to figure 1, you can see where the wire splices together. You have to clean the enamel off the wire so you can make a good electrical connection here. Also, a 25 watts pencil tip soldering iron will not do the job here. You must use a high wattage (100+ watts) iron or even a propane torch to solder the wires together. If you merely make a physical connection by twisting and not soldering, eventually over time when the wire “rusts” the connection will go bad (ask me how I know). Now, extend the spread arms out enough just to hold the wire taunt. Figure 6 shows how tight you should make the spreader arms.

Figure 5 – The Balun, simplifies hooking the coax to the driven element wire among other important things. The balun is secured to the spread arm with tie-wraps and outdoor electrical tape (I like 3M’s). Notice here also, the area you should waterproof when you are done, by wrapping either electrical tape around it, or Radio Shacks coax seal.

Figure 7 – The driven element shown with balun at the feedpoint. Fed for horizontal polarization.

Figure 8 – The driven element shown with a balun at the feedpoint. Fed for vertical polarization. You can see the feed line has to run down the spreader arm. I recommend horizontal polarization!

Figure 9 – Shows how much tension to put on the wire. You adjust the tension by extending the spreader arm length or moving your wire holder up the spreader arm, depending on how you made your spreader arms.

For the driven element, make the connection to the balun like shown in figure 5. You want to solder one side of the connection good. The other side you first just want to twist the wires together, making sure there is a good physical connection. We may have to do some adjusting here, so we need to temporarily make this connection this way. After the elements are strung, its time to place them on the boom. Make sure everything is tight and then hoist the antenna into its position (on the tower or mast where you are going to mount it). Connect the coax, and check the SWR. Confirm that the SWR is where you want it to be. This is one place where you cannot expect it to be 1:1 exactly where you designed it for. However it should be close! I designed my beam to be 1:1 on 27.555MHz and it ended up being 1:1 on 27.625MHz. I did not even bother to adjust the beam any further…it was close enough for me. So, lets say that you get it all together and its not close enough for you. We will use the situation that I found when I first checked the SWR. My antenna was 1:1 on 27.625MHz. Since we want the SWR to be 1:1 on 27.555MHz, this means we need to lengthen the driven element wire. By how much? We definitely do not want to have to do this 3 times because you know if we shorten or lengthen our wire now those 90 degree bends we made in our wire will have to move and we will have to bend new corners. The best way to figure out how much you will need to lengthen or shorten the wire is to calculate the length. Since we know that we are 1:1 on 27.625, we can calculate the distance that should be close. You will need to add about 1 1/8 inches of length to the loop. Hopefully you have left enough extra beyond the corner mark to add the 1 1/8. If not, you will have to solder extra length on. But If you have planned right..you shouldn’t have to be doing that! Adding 1 1/8 of an inch to the loop adds a little over 1/4 inch to each side of the loop. Now, lets say your SWR was 1:1 on 27.485MHz and you wanted it to be 1:1 on 27.555MHz. You would need to then shorten the wire by 1 1/8 of an inch. How did I know to the exact length (1 1/8) to lengthen or shorten? I calculated it using simple algebra. More simply, you could just go about adding (or cutting depending on which way your SWR is off) a 1/2 inch at a time, then recheck the SWR. If you need to move the SWR down (ex. from 27.625 to 27.555), then lengthen, if you need to move it up (ex. from 27.485 to 27.555) then shorten the wire, simple. Ok, this is just great, I go through all this..and the SWR is higher than 3:1 on 27.555MHz! Do not fret! I was once told…”If your antenna works right the first time, you did something wrong!”. Ok, if your SWR is sky high, relax, you have a bad connection somewhere. Is there a good connection on all the wires on the parasitic elements? Maybe that enamel is causing one of your elements to be an open circuit? If have done everything correctly to this point, your SWR should be around where you designed it for….if its not, bad connection—somewhere! Antenna building is not rocket science! Hopefully, when you get your quad together, it is close enough where you do not have to make any further adjustments. Depending on the surrounding objects (trees, towers, etc.) or the way you made the supporting structure and what wire size you used, you may have to do some adjusting.

After you have gotten the SWR where you want it, its time to solder that other side to the balun. When I was done making the connections, I then coated the connection with enamel…to further protect the wires from “rusting”.

So there you have it. If you have read this far and are really thinking about doing it…do it! You should get together some other books about quads and do some more reading. Definitely, email me with your questions and comments. When you are all done with this one, you will have an antenna that has 2db more than a Moonraker 4, is quieter on receive, and is better for DX because of its polarization insensitive parasitic elements! I look forward to hearing from you on the air someday.

73s

Article by Scott, 2 Romeo Papa 789 originally available at http://signalengineering.com:80/ultimate/4_element_quad.html

I followed your directions step by step making a four element qaud out of an old moonraker 4. You are very right, the antenna works wonderful. It gives out a 2db more signal and louder audio over a moon racker4 . Thanks. Rusty 2WR7111 Wagener SC